Need

For some time, GeneXus Consulting has been supporting the digital transformation of ANCAP, specifically in the Digital Dispatch program.

This program aims to automate and optimize the operations related to fuel dispatch, distribution, and delivery processes in ANCAP’s different plants. In these first phases, special emphasis is being placed on the La Tablada plant, which is the most in-demand.

Solution

The project comprised several phases:

Phase 1: Application for Transporters

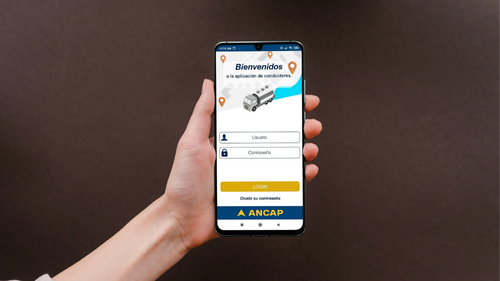

The creation of an application specifically designed for drivers was promoted to improve communication between all stakeholders: ANCAP, distributors, transporters, and the drivers themselves.

The application displays information on trips scheduled for the current day and the following day, with details of the products to be delivered to each customer. As trucks arrive at the plant, the plant personnel assign loading bays based on the turn, number, and arrival time, and this information is sent to the application for the driver to view and enter the loading bay.

Phase 2: Elimination of Physical Documentation

Given the health situation in the country, it was considered a fundamental objective to eliminate physical documentation used in the plant for the dispatch process to improve hygiene conditions and streamline the process.

In this stage, the digital transformation of the plant floor subprocess that involved document exchange between distributors and ANCAP was completed so that drivers did not have to physically present the documents at the Plant Administration.

In turn, the automated virtual ordered list of loads was implemented based on the programming of the distributors and the driver’s arrival time at the plant, a task that was performed manually by the plant staff every day.

Phase 3: Driver Identification

This phase aimed to advance with the automation of driver identification to ensure their qualification and control their entry into the plant.

The development and Security teams of GeneXus Consulting worked together with the ANCAP Information Technology team on the project, making the totems operational at the La Tablada plant to facilitate digital entry registration. Access control can be done in two ways: through a PIN or fingerprint.

Phase 4: Digital Schedule

In this phase, the Digital Fuel Schedule was introduced, which allowed achieving the following objectives: optimizing loading bays, reducing waiting times for trucks that wait to load products in the different fuel loading bays that ANCAP has in its “La Teja” plant and distribution plants in “La Tablada,” Paysandú, Treinta y Tres, Juan Lacaze, and Durazno, and enhancing communications between different stakeholders by visualizing the dispatch capacity of each plant (quota and resulting balance).

Future phases

We continue working with the ANCAP team on the definition of solutions that continue to improve their logistics. Currently, we are designing a solution for the parking lot (in this case, La Tablada Plant) to try to minimize the time each truck spends waiting for its turn, which will also help relieve congestion in that area, providing greater operational safety.